Transform Your Testing Workflow with a State-of-the-Art Dirt Screen for Sale

Transform Your Testing Workflow with a State-of-the-Art Dirt Screen for Sale

Blog Article

Enhance Product Recovery With State-Of-The-Art Dust Screens for Recycling Facilities

In today's world, where ecological sustainability is a pressing problem, reusing facilities play a critical function in reducing waste and preserving sources. Taking full advantage of product recuperation can be a complex process, commonly prevented by the presence of dirt and particles in the reusing stream. This is where state-of-the-art dirt screens enter play, offering an appealing solution to improve product healing prices. By efficiently separating undesirable contaminants, these sophisticated screens hold the possible to transform reusing centers' procedures. Just how exactly do dirt screens enhance material recovery? What are the essential functions that make them advanced? And exactly how can reusing centers execute them properly? In this discussion, we will certainly check out the responses to these inquiries and explore real-life case studies that highlight the effective assimilation of dust displays in recycling facilities. Prepare to find the transformative power of advanced dirt screens and their influence on enhancing material healing.

The Value of Dust Screens in Recycling Facilities

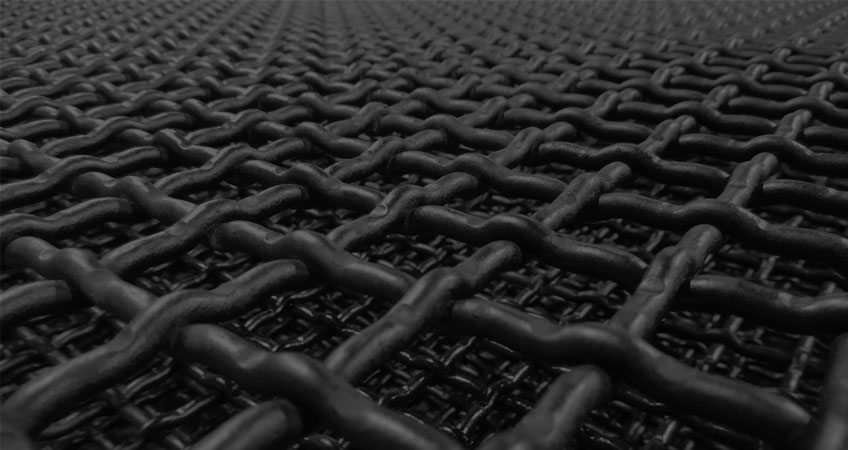

Dirt screens play an essential function in reusing centers by successfully dividing dirt and various other pollutants from recyclable materials. These screens, additionally called trommel screens, are developed to efficiently get rid of unwanted particles and make certain that functional and only tidy materials are processed additionally.

The main function of dirt displays is to separate bigger items of dust, rocks, and other non-recyclable items from the stream of products. By doing so, they avoid these contaminants from going into the recycling procedure and potentially damaging equipment or endangering the top quality of the end product.

Furthermore, dust screens assist to boost the total performance of reusing operations. By removing dust and various other impurities early in the procedure, the displays lower the quantity of manual work called for to sort and clean the products later. This not only saves time yet also boosts and decreases expenses performance.

Moreover, using dirt displays adds to ecological sustainability. By ensuring that just clean and uncontaminated products are processed, reusing facilities can generate higher-quality recycled products. This, consequently, motivates making use of recycled products in various industries, lowering the need for virgin resources and reducing the environmental effect of resource removal and production processes.

Exactly How Dirt Screens Improve Product Recuperation

Utilizing dirt displays in recycling centers substantially improves the procedure of product recovery. These displays play an essential role in dividing dirt, particles, and other unwanted materials from the recyclable stream, leading to boosted performance and better outcome.

Among the main ways in which dirt screens boost product recovery is by removing impurities that can impede the recycling procedure. Dirt, rocks, and various other non-recyclable items can cause damages to tools, lower the performance of succeeding sorting procedures, and contaminate the final recycled materials. By effectively screening out these impurities, dust screens assist ensure that the recyclable products stay pure and of excellent quality.

Moreover, dust screens make it possible for reusing centers to recoup a higher quantity of useful materials. By removing dirt and particles, the screens enable a more exact sorting process, enhancing the healing price of recyclable materials. This indicates that better sources can be recovered and recycled, reducing the demand for virgin products and reducing the ecological impact related to their removal and production.

In enhancement to enhancing material recovery, dirt displays likewise add to the overall efficiency of recycling centers. By stopping equipment damage and lowering downtime triggered by blockages and clogs, these displays help preserve a smooth and continuous recycling process. This raised efficiency equates right into expense savings and allows for greater throughput, eventually improving the profitability and sustainability of reusing operations.

Trick Attributes of State-of-the-Art Dirt Screens

To additionally improve the effectiveness and effectiveness of product recovery in reusing facilities, cutting edge dirt displays are geared up with essential attributes that optimize the splitting up procedure and make certain the best outcome (dirt screen for sale). These features consist of advanced screening technology, customizable setups, and robust construction

One trick feature of cutting edge dust screens is their advanced official website testing innovation. These displays are designed with precision-engineered mesh or perforated plates that properly separate dirt and debris like it from the recyclable products. The size and spacing of the openings in the screens can be personalized to suit various sorts of products, allowing for effective splitting up and optimum recuperation rates.

Another crucial feature of these dirt displays is their personalized setups. Recycling centers can change the rate, angle, and amplitude of the displays to optimize the splitting up procedure. This versatility permits operators to make improvements the displays according to the details needs of the products being processed, leading to enhanced accuracy and higher healing prices.

Moreover, advanced dirt displays are built with robust construction to withstand the severe problems of recycling facilities. They are made from long lasting products such as stainless-steel or high-strength alloys, making sure long life and marginal downtime as a result of maintenance or repair services. Furthermore, these screens are designed with simple access for cleaning and maintenance, promoting efficient operations and reducing downtime.

Steps to Carrying Out Dust Screens in Recycling Facilities

What are the required actions for incorporating dust screens right into reusing facilities? Executing dust displays in reusing facilities includes an organized technique to make sure effective installment and procedure. The complying with are the necessary steps to efficiently integrate dust screens:

Assessment: Conduct a detailed assessment of the facility's needs and requirements to determine the appropriate dust screen specs. Think about aspects such as material kind, volume, and desired separation performance.

Setup: Prepare the facility for the installation of the dirt screens. Comply with supplier guidelines and guarantee correct positioning and assimilation with the reusing procedure.

Examining and Calibration: Once the dirt displays are installed, perform detailed testing to guarantee proper functioning. dirt screen for sale. Calibrate the system to accomplish preferred splitting up efficiency and reduce worldly loss

Training and Upkeep: Train personnel on operating and preserving the dirt display system. Develop a normal maintenance routine, consisting of cleaning and evaluation, to guarantee ideal performance and durability.

Situation Studies: Successful Material Healing With Dirt Screens

Incorporating dust displays into reusing centers has shown to be an effective method view for achieving reliable material healing, as demonstrated by several case researches. These study highlight the favorable influence of dirt screens on the general recycling procedure.

By applying dirt displays, the facility was able to substantially minimize the amount of contamination in their recyclable products. The intro of dirt displays additionally aided to reduce the wear and tear on sorting devices, reducing upkeep prices and downtime.

An additional case research study showcases a rural recycling facility that fought with extreme dirt and particles in their incoming waste stream. By installing dust screens, the center was able to eliminate a large section of the unwanted materials, resulting in cleaner recyclables and enhanced efficiency in the arranging process. This caused greater material recuperation rates and minimized waste sent to the landfill.

These study demonstrate that integrating dirt screens right into recycling facilities can have a substantial favorable effect on material healing. By efficiently getting rid of dirt, particles, and other pollutants, recycling facilities can boost their overall recycling prices, reduce land fill waste, and maximize the worth of recovered products.

Final Thought

Finally, using cutting edge dust displays in reusing centers is important for improving product healing. These displays properly remove dirt and particles, permitting the efficient separation and healing of beneficial materials. By applying dust screens, reusing centers can substantially enhance their reusing procedures and add to a much more sustainable future.

One of the major methods in which dirt displays improve material recuperation is by removing contaminants that can prevent the recycling process. By efficiently evaluating out these pollutants, dust screens help guarantee that the recyclable products remain pure and of high quality.

Furthermore, dirt displays make it possible for recycling centers to recuperate a greater amount of important products.In addition to enhancing material healing, dust screens additionally add to the total performance of reusing centers.In conclusion, the use of state-of-the-art dirt screens in reusing facilities is essential for improving product recovery.

Report this page